“Cleanliness is next to godliness”; sage advice on the importance of clarity and spotlessness for higher functions to be carried out in our lives. When it comes to the safety, function and maintenance of your earthmoving and mining equipment, the properties of cleanliness and attention to detail remain just as divine.

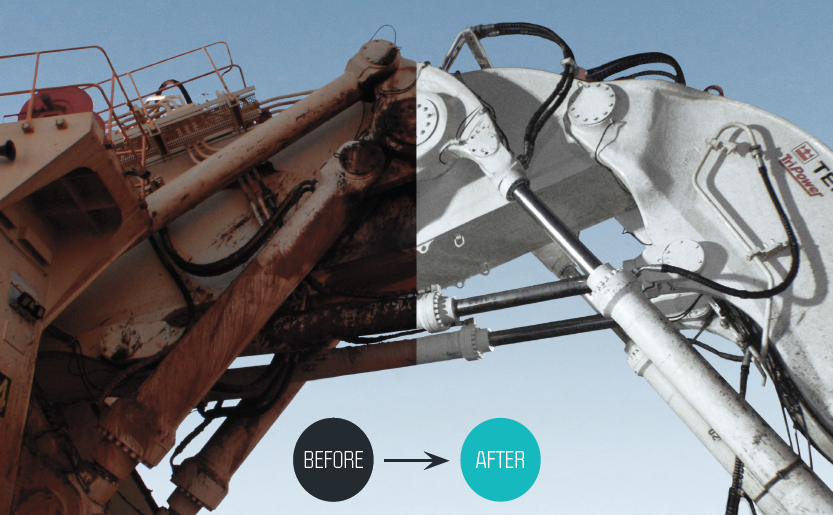

Attention to detail is an essential quality in HD fitters working on mining sites. They are generally required to inspect, repair and maintain heavy equipment. But how can a fitter spot a problem when it’s obscured under layers of grease, grime and dirt? Mechanics can’t fix what they can’t see.

This problem led Darren Waters to start the Pilbara Clean Machines, or TPCM, in 2006.

“I was the branch manager for Hitachi, where I had to organise all the NDT work for customers, and their equipment was always too dirty,” said Darren.

Now part of the Schlam, TPCM has over 60 employees who work with clients such as FMG, BHP, Rio Tinto, Mineral Resources and Macmahon.

He explains that machines traditionally come in for their major annual repair, where they are checked for significant structural damage. However, performing this inspection is always easier if the equipment is as clean as it can be.

"These inspections are visual, so the extra time that we spend cleaning a machine is made back in spades. The true value of what we do is that these guys can quickly perform a thorough inspection and get their equipment back into operation faster," said Darren.

The cleaning rigs that TPCM uses are purpose-built. According to Darren, they spray at around 4,000 psi and 80 degrees celsius, which is just hot enough to melt grease. They also inject soap into the water to soften it up. On a single piece of equipment, a crew of four people will use 15,000 litres or 20 litres per operator per minute.

Darren says is it would have to be one of the dirtiest jobs in the world, but despite this, it's pretty fulfilling and enjoyable to reveal the face beneath the grime, grease, and impurities.

“It’s quite relaxing. Plus, you can see your progress, and you get a sense of satisfaction when you finish the job at the end of the day,” he says.

Troy Spencer, who has been with the company for five and a half years, agrees that pressure cleaning is a love-it or hate-it job experience but that the outcomes for safety and cost are vital to the client and a bonus source of satisfaction for workers. A clean machine means avoiding low-quality, incomplete, and out-of-budget repairs.

Despite having some pressure washing experience, Mr Spencer admits that working in the mining industry was a bit of a culture shock.

“The resources industry is a different ballgame. I wasn’t aware of all the safety requirements,” he says.

“With pressure washing, you can’t be in the line of fire. We start high and always aim at the ground or away from the equipment.”

On top of this, workers are fitted out with all the correct PPE, including visors and steel cap gumboots. Guys also wear paper and plastic overalls like a surgeon, which they can remove in a hurry when they knock off at the end of their shift.

TPCM’s personnel are all highly-trained according to AS/NZS 4233.1-2013 high-pressure water jetting systems safety standards to handle equipment in the right way, and the team is committed to providing excellent customer service. The services can be relocated anywhere in Australia to ensure that professional cleaning is carried out on-site with the specifically built and customised vehicles fleet.

To get your machines free from grease and grime for optimal safety and maintenance, call the team at TPCM on (08) 9189 1136 or email TPCM@Schlam.com