Our sophisticated design capabilities enable us to offer clients completely customised solutions to the most complex issues.

This was demonstrated through a pipe redesign and replacement undertaken for a long-standing client.

Our sophisticated design capabilities enable us to offer clients completely customised solutions to the most complex issues.

This was demonstrated through a pipe redesign and replacement undertaken for a long-standing client.

.jpg?width=876&height=425&name=20150319_115%20(ID%2061865).jpg)

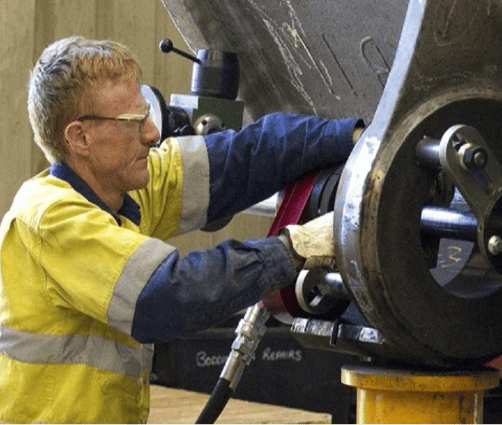

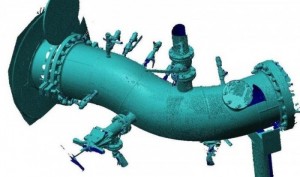

The pipe had been marked for replacement but there were no existing drawings/plans to manufacture a new one. The replacement pipe also required a number of updated features and there was a seven day deadline to complete the job.

Schlam utilised its sophisticated 3D laser scanning and CAD modelling services to go to the site and scan the pipe while it was in position. From this scan, a model was created using top-range software and the new features were incorporated, including the removal of unneeded branches, sockets and leak detection plates. A fixture for the fabrication to hold the major flanges in position was modelled so all of the connections would line up perfectly when the pipe was completed.

The pipe was scanned, modelled, designed, manufactured and fitted within the seven day deadline. The work was scanned again in the Schlam workshop prior to welding to ensure correct flange orientation and pipe position. The welds were subjected to NDT and x-ray before delivery to site and passed with no problems. No modifications were required during fitting and the client was extremely happy with how well the pipe fitted.